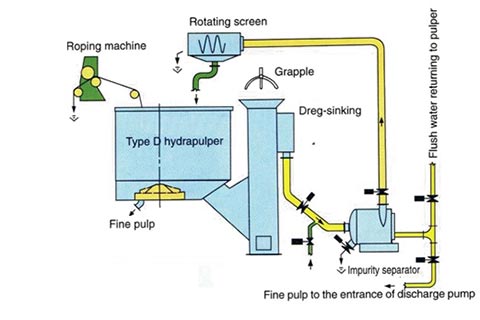

Continuous Pulping & Impurities-removing System

D Type Continuous Pulping & Impurities-removing System is mainly used for pulping LOCC, AOCC and other waste paper raw material.

D Type Continuous Pulping & Impurities-removing System is mainly used for pulping LOCC, AOCC and other waste paper raw material.

This system can remove light & heavy impurities before the slurry goes into pulper sieve plate, thus the content of impurities in pulper is decreased, the pulping process can keep going, and the production capacity can improve.

D Type Continuous Pulping & Impurities-removing System consists of D Type Hydrapulper, Sediment Well, Reject Separator, Drum Screen, Ragger, Rope Cutter, Grapple, etc.

D Type Hydrapulper & Sediment Well are the main parts of continuous pulping & impurities-removing system;

Reject Separator discharges impurities termly from Hydrapulper;

Drum Screen mainly discharges the water which is used for cleaning Reject Separator;

Ragger is used for removing the big twisting impurities in D Type Hydrapulper;

Rope Cutter is mainly used for cutting down the twisting impurities handled by Ragger and making them easier to transport.

Grapple is mainly used for remove the heavy impurities in Sediment Well.

Leizhan is a professional manufacturer of pulping & paper making equipments. If you are interested in any of our products, please feel free to contact us for further details.

Email: leizhanpapermachine@gmail.com