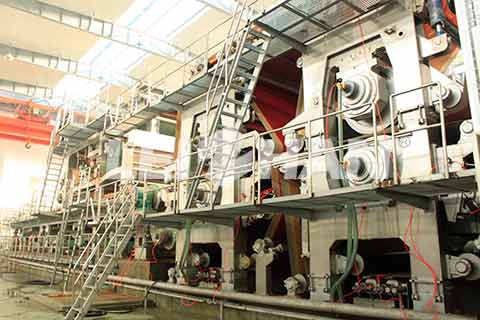

5200MM Double Layer Wire Paper Machine

5200MM Double Layer Wire Paper Machine is developed based on the experience of multiple papermaking projects for the production of 70-180g/m2 T paper and corrugated paper and other paper types. Its product is roll paper. The production capacity of this paper machine can reach 400td, which is an important equipment for large-scale paper roll production.

Main Information

Main products: High-strength corrugated paper, T paper, liner paper

Production capacity: 400t/d (110g, 500m)

Trimmed width: 5200mm

Quantitative range: 70-180g/m2

Working speed: 500-550m/min

Design speed: 600m/min

Gauge: 6400mm (determined by final design)

As a leading paper machinery company, Leizhan Company not only provides advanced paper machines but also provides a complete set of high-quality pulping equipment. Email: leizhanpapermachine@gmail.com